Mather and Platt - Single Stage Split Casing Pumps - Single Stage Split Casing Pumps ALE to EME Ranges

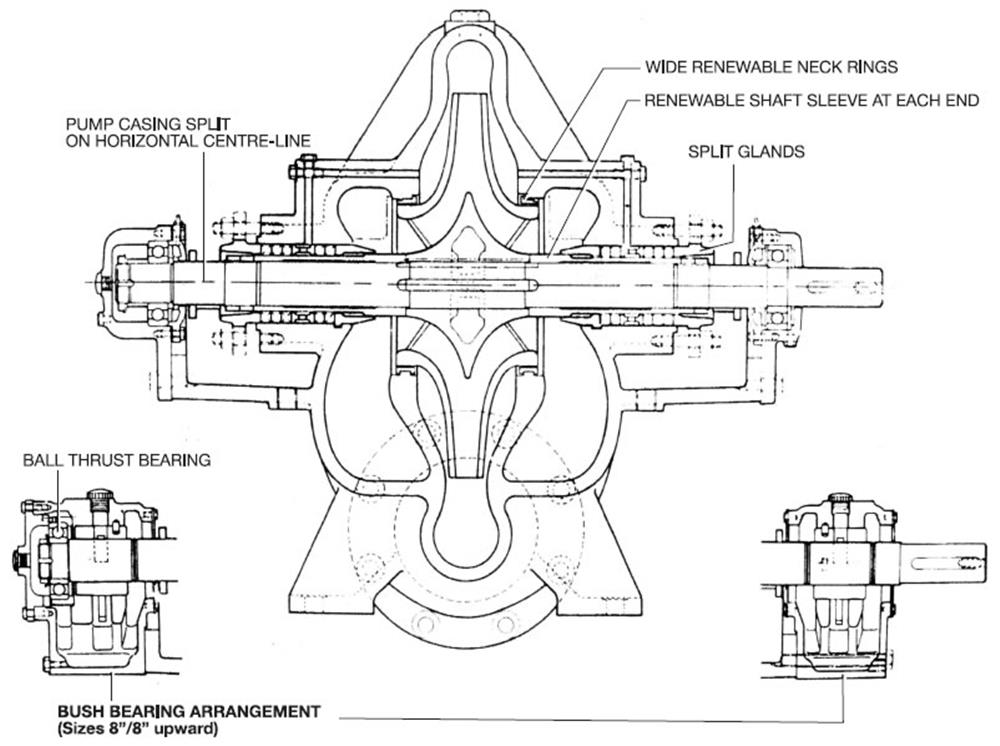

General Features

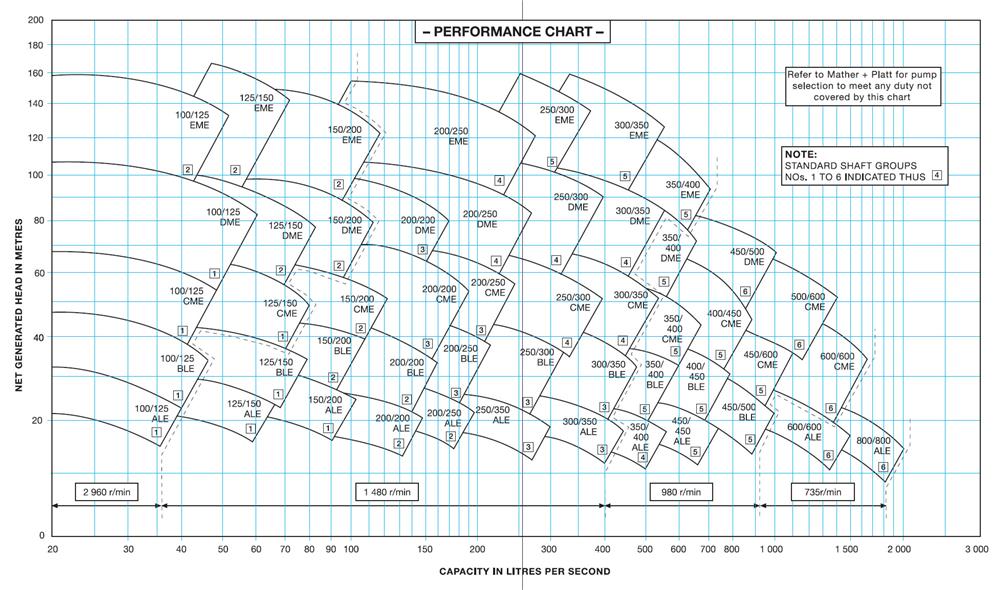

The ALE to EME range of pumps form a comprehensive range of heavy duty single stage horizontally split-casing pumps covering all capacities up to 2 000 l/s and heads up to 160 meters.

The range has been designed in its standard form for all general industrial applications and optional features are readily available for special applications involving corrosion, abrasion and high temperatures, which may be encountered in steelworks, chemical plants, refineries etc.

A double entry impeller is fitted to minimise axial thrust, and on large units a double volute casing is employed to limit radial forces.

The shaft assembly complete with cartridge type bearing sub-assemblies, can be removed from the pump by removing the top half casing, without disturbing main pipework connections.

The complete range has been designed to give maximum interchangeability of wearing parts between different pump sizes and is built round only 6 shaft groups each comprising shaft, sleeves and complete bearing assemblies. At the same time the impeller can be adjusted easily to give "tailor-made" performance anywhere within the range.

The pumps are suitable for direct coupled drive by electric motor, turbine or I.C. engine. Vertical operations with open or closed-type shafting can be provided.

Specification (Standard Pump)

Shaft, Locknut & Ring: Steel

Impellar: Bronze or Cast Iron

Neck Rings: Bearing Bronze or Cast Iron

Stuffing Box Bushes: Bearing Bronze or Cast Iron

Lantern Rings: Polyethelene

Sleeves and Nuts: Bronze or Cast Iron

Glands: Bronze

Packing: Graphite Cotton

Bearing End Covers: Cast Iron

Water Throwers: Rubber

Bearings: Anti Friction Ball (See alternative specifications)

Bearing Lubrications: Grease

Lantern Rings: Polyethelene

Flange Drilling: To match BS 4504 or equivalent standard

Alternative Specifications

The units can be supplied with one or more of the following features:

- Horizontally split, bronze/white metalled sleeve bearings provided with oil ring lubrication and an anti-friction thrust unit at the pump free end.

- Mechanical Seals

- Impellar wearing rings

- Flanges and fittings to suit preferred national other standards e.g. A.P.I. or D.I.N.

- A Wide range of alternative material selection suit any particular special operating condition customer preference

- Gland design adaptable for either international external sealing water service as may be required

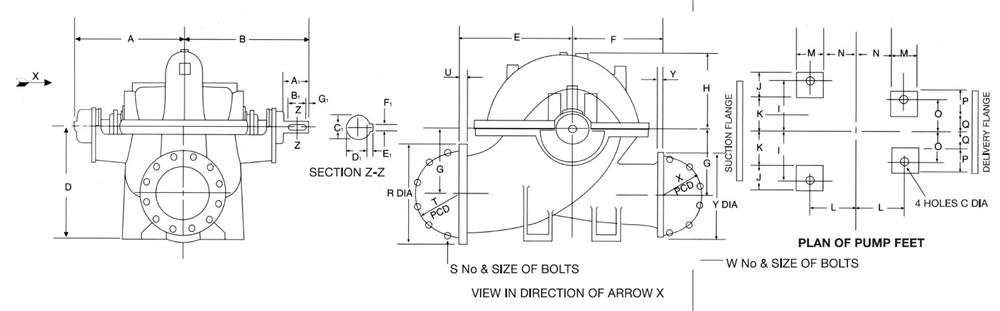

Shaft Extension Details

Scroll table left or right for small devices.

| Shaft group | A1 | B1 | C1 | D1 | E1 | F1 | G1 |

| 1 | 88 | 77 | 29,02 29,03 | 0,996" 0,990" | 1/4" | 311" 312" | 5 |

| 2 | 104 | 83 | 39,04 39,02 | 1,349" 1,343" | 5/16" | 437" 438" | 5 |

| 3 | 137 | 102 | 54,04 54,02 | 1,866" 1,860" | 7/16" | 624" 625" | 6 |

| 4 | 160 | 126 | 69,04 69,02 | 2,418" 2,413" | 1/2" | 749" 750" | 6 |

| 5 | 182.5 | 140 | 79,05 79,02 | 2,740" 2,734" | 5/8" | 874" 875" | 6 |

| 6 | 187.5 | 140 | 94,05 94,03 | 3,258" 3,253" | 3/4" | 999" 1000" | 6 |

Dimensions

NB: 'Size' Designates Nominal Delivery / Suction Branch Diameters. Scroll left or right for small devices.

| Shaft group | Type | Size | A | B | AA | BB | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ALE | 100/125 | 370 | 416 | - | - | 18 | 279 | 250 | 220 | 135 | 145 | 150 | 100 | 85 | 110 | 100 | 60 | 95 | 100 | 30 | 250 | 8/16 | 210 | 26 | 220 | 8/16 | 180 | 24 |

| BLE | 100/125 | 370 | 416 | - | - | 18 | 279 | 250 | 220 | 140 | 152 | 150 | 100 | 85 | 110 | 100 | 60 | 95 | 100 | 30 | 240 | 8/16 | 210 | 26 | 220 | 8/16 | 180 | 24 | |

| CME | 100/125 | 370 | 416 | - | - | 18 | 254 | 250 | 230 | 145 | 170 | 150 | 100 | 85 | 110 | 100 | 60 | 95 | 100 | 30 | 250 | 8/16 | 210 | 26 | 220 | 8/16 | 180 | 24 | |

| DME | 100/125 | 370 | 416 | - | - | 18 | 279 | 280 | 250 | 170 | 195 | 150 | 100 | 85 | 110 | 100 | 60 | 95 | 100 | 30 | 250 | 8/16 | 210 | 26 | 220 | 8/16 | 180 | 24 | |

| ALE | 125/150 | 370 | 416 | - | - | 18 | 318 | 337 | 280 | 197 | 225 | 150 | 100 | 85 | 110 | 100 | 60 | 95 | 100 | 30 | 285 | 8/20 | 240 | 26 | 250 | 8/16 | 210 | 26 | |

| BLE | 125/150 | 370 | 416 | - | - | 18 | 318 | 356 | 318 | 216 | 255 | 150 | 100 | 85 | 110 | 100 | 60 | 95 | 100 | 30 | 285 | 8/20 | 240 | 26 | 250 | 8/16 | 210 | 26 | |

| CME | 125/150 | 370 | 416 | - | - | 18 | 279 | 305 | 267 | 162 | 183 | 150 | 100 | 85 | 110 | 100 | 60 | 95 | 100 | 30 | 285 | 8/20 | 240 | 26 | 250 | 8/16 | 210 | 26 | |

| ALE | 150/200 | 370 | 416 | - | - | 18 | 343 | 381 | 280 | 203 | 250 | 150 | 100 | 85 | 110 | 100 | 60 | 95 | 100 | 30 | 340 | 12/20 | 295 | 30 | 285 | 8/20 | 240 | 26 | |

| 2 | EME | 100/125 | 377 | 440 | - | - | 18 | 266 | 330 | 280 | 190 | 225 | 126/50 | 146/80 | 0 | 125 | 100 | 90 | 61/59 | 80 | 0 | 270 | 8/24 | 220 | 30 | 235 | 8/20 | 190 | 28 |

| DME | 125/150 | 411 | 474 | - | - | 22 | 318 | 330 | 280 | 184 | 210 | 150 | 100 | 85 | 110 | 120 | 50 | 95 | 100 | 30 | 285 | 8/20 | 240 | 26 | 250 | 8/16 | 210 | 26 | |

| EME | 125/150 | 381 | 444 | - | - | 18 | 333 | 302 | 266 | 226 | 255 | 125 | 105 | 65 | 160/120 | 100 | 110/70 | 100 | 95 | 50 | 300 | 8/24 | 250 | 34 | 270 | 8/24 | 220 | 30 | |

| BLE | 150/200 | 411 | 474 | - | - | 22 | 343 | 406 | 330 | 229 | 280 | 200 | 100 | 135 | 160 | 120 | 100 | 130 | 100 | 65 | 340 | 12/20 | 295 | 30 | 285 | 8/20 | 240 | 26 | |

| CME | 150/200 | 411 | 474 | - | - | 22 | 426 | 432 | 381 | 274 | 305 | 200 | 100 | 135 | 160 | 120 | 100 | 130 | 100 | 65 | 340 | 12/20 | 295 | 30 | 285 | 8/20 | 240 | 26 | |

| DME | 150/200 | 411 | 474 | - | - | 22 | 343 | 369 | 330 | 203 | 216 | 200 | 100 | 135 | 160 | 120 | 100 | 130 | 100 | 65 | 340 | 12/20 | 295 | 30 | 285 | 8/20 | 240 | 26 | |

| EME | 150/200 | 411 | 474 | - | - | 22 | 369 | 407 | 350 | 229 | 244 | 200 | 100 | 135 | 160 | 120 | 100 | 130 | 100 | 65 | 360 | 12/24 | 310 | 34 | 300 | 8/24 | 250 | 34 | |

| ALE | 200/200 | 411 | 474 | - | - | 22 | 343 | 407 | 317 | 227 | 270 | 200 | 100 | 135 | 160 | 120 | 100 | 152 | 100 | 87 | 340 | 12/20 | 295 | 30 | 340 | 12/20 | 295 | 30 | |

| BLE | 200/200 | 411 | 474 | - | - | 22 | 426 | 407 | 375 | 248 | 290 | 200 | 100 | 135 | 160 | 120 | 100 | 152 | 100 | 87 | 340 | 12/20 | 295 | 30 | 340 | 12/20 | 295 | 30 | |

| ALE | 200/250 | 411 | 474 | - | - | 22 | 426 | 432 | 318 | 248 | 290 | 200 | 100 | 135 | 160 | 120 | 100 | 152 | 100 | 87 | 395 | 12/20 | 350 | 28 | 340 | 8/20 | 295 | 26 | |

| 3 | CME | 200/200 | 525 | 612 | 608 | 696 | 26 | 426 | 483 | 432 | 292 | 336 | 200 | 120 | 115 | 160 | 135 | 92.5 | 152 | 114 | 73 | 340 | 12/20 | 295 | 30 | 340 | 8/20 | 295 | 30 |

| DME | 200/200 | 525 | 612 | 608 | 696 | 22 | 464 | 470 | 457 | 343 | 370 | 200 | 120 | 115 | 160 | 135 | 92.5 | 152 | 114 | 73 | 340 | 12/20 | 295 | 30 | 340 | 8/20 | 295 | 30 | |

| BLE | 200/250 | 525 | 612 | 608 | 696 | 26 | 464 | 483 | 381 | 292 | 315 | 200 | 120 | 115 | 160 | 135 | 92.5 | 152 | 114 | 73 | 504 | 12/24 | 355 | 32 | 340 | 8/20 | 295 | 30 | |

| CME | 200/250 | 525 | 612 | 608 | 696 | 26 | 464 | 483 | 457 | 299 | 350 | 200 | 120 | 115 | 160 | 135 | 92.5 | 152 | 114 | 73 | 395 | 12/20 | 350 | 28 | 340 | 8/20 | 295 | 26 | |

| ALE | 250/300 | 525 | 612 | 608 | 696 | 26 | 464 | 508 | 337 | 273 | 330 | 250 | 120 | 165 | 160 | 135 | 92.5 | 152 | 114 | 73 | 460 | 12/24 | 410 | 32 | 405 | 12/24 | 355 | 32 | |

| BLE | 250/300 | 525 | 612 | 608 | 696 | 26 | 546 | 533 | 432 | 317 | 360 | 250 | 120 | 165 | 160 | 135 | 92.5 | 152 | 114 | 73 | 460 | 12/24 | 410 | 32 | 405 | 12/24 | 355 | 32 | |

| ALE | 300/350 | 525 | 612 | 608 | 696 | 24 | 546 | 565 | 390 | 318 | 371 | 260 | 120 | 165 | 160 | 135 | 92.5 | 152 | 114 | 73 | 520 | 16/24 | 470 | 36 | 460 | 12/24 | 410 | 32 | |

| BLE | 300/350 | 525 | 612 | 608 | 696 | 22 | 546 | 559 | 391 | 318 | 375 | 260 | 120 | 165 | 160 | 135 | 92.5 | 152 | 114 | 73 | 505 | 16/20 | 460 | 30 | 445 | 12/20 | 400 | 28 | |

| 4 | DME | 200/250 | 594 | 693 | 677 | 800 | 26 | 546 | 521 | 458 | 356 | 395 | 275 | 150 | 175 | 230 | 150 | 155 | 200 | 150 | 100 | 405 | 12/24 | 355 | 32 | 340 | 12/20 | 295 | 30 |

| EME | 200/250 | 594 | 693 | 677 | 800 | 26 | 680 | 682 | 500 | 435 | 449 | 275 | 150 | 175 | 230 | 150 | 155 | 200 | 150 | 100 | 425 | 12/27 | 370 | 36 | 360 | 12/24 | 310 | 34 | |

| CME | 250/300 | 594 | 693 | 677 | 800 | 26 | 546 | 534 | 457 | 343 | 380 | 275 | 150 | 175 | 230 | 150 | 155 | 200 | 150 | 100 | 460 | 12/24 | 410 | 32 | 405 | 12/24 | 355 | 32 | |

| DME | 250/300 | 594 | 693 | 677 | 800 | 26 | 546 | 584 | 492 | 356 | 415 | 275 | 150 | 175 | 230 | 150 | 155 | 200 | 150 | 100 | 460 | 12/24 | 410 | 32 | 405 | 12/24 | 355 | 32 | |

| CME | 300/350 | 594 | 693 | 677 | 800 | 26 | 591 | 584 | 483 | 343 | 405 | 300 | 150 | 200 | 230 | 150 | 155 | 250 | 150 | 150 | 520 | 16/24 | 470 | 36 | 460 | 12/24 | 410 | 32 | |

| DME | 300/350 | 594 | 693 | 677 | 800 | 26 | 591 | 629 | 534 | 378 | 440 | 300 | 150 | 200 | 230 | 150 | 155 | 250 | 150 | 150 | 520 | 16/24 | 470 | 36 | 460 | 12/24 | 410 | 32 | |

| ALE | 350/400 | 594 | 693 | 677 | 800 | 26 | 686 | 698 | 464 | 407 | 460 | 380 | 150 | 280 | 230 | 200 | 130 | 320 | 150 | 120 | 565 | 16/24 | 515 | 32 | 505 | 16/20 | 460 | 30 | |

| 5 | EME | 250/300 | 643 | 764.5 | 721 | 917 | 26 | 622 | 635 | 559 | 407 | 476 | 270 | 120 | 200 | 270 | 180 | 180 | 170 | 120 | 100 | 485 | 16/27 | 430 | 40 | 425 | 12/27 | 370 | 36 |

| EME | 300/350 | 673 | 794.5 | 751 | 887 | 30 | 686 | 660 | 610 | 445 | 476 | 380 | 150 | 280 | 300 | 200 | 200 | 220 | 150 | 120 | 555 | 16/30 | 490 | 44 | 485 | 9/16 | 430 | 40 | |

| BLE | 350/400 | 703 | 824.5 | 781 | 917 | 26 | 686 | 737 | 559 | 445 | 500 | 380 | 150 | 280 | 300 | 200 | 200 | 220 | 150 | 120 | 565 | 16/24 | 515 | 32 | 505 | 16/20 | 460 | 30 | |

| CME | 350/400 | 703 | 824.5 | 781 | 917 | 26 | 686 | 762 | 619 | 457 | 520 | 380 | 150 | 280 | 300 | 200 | 200 | 220 | 150 | 120 | 565 | 16/24 | 515 | 32 | 505 | 16/20 | 460 | 30 | |

| DME | 350/400 | 703 | 824.5 | 781 | 917 | 26 | 762 | 813 | 711 | 495 | 600 | 380 | 150 | 280 | 300 | 200 | 200 | 220 | 150 | 120 | 565 | 16/24 | 515 | 32 | 505 | 16/20 | 460 | 30 | |

| EME | 350/400 | 703 | 824.5 | 781 | 917 | 35 | 762 | 848 | 580 | 512 | 565 | 355 | 200 | 205 | 500/300 | 200 | 400/200 | 195 | 150 | 95 | 620 | 16/33 | 550 | 48 | 555 | 16/30 | 490 | 44 | |

| ALE | 450/450 | 703 | 824.5 | 781 | 917 | 26 | 762 | 762 | 578 | 457 | 510 | 380 | 150 | 280 | 300 | 200 | 200 | 220 | 150 | 120 | 640 | 20/27 | 585 | 40 | 640 | 20/27 | 585 | 40 | |

| BLE | 400/450 | 703 | 824.5 | 781 | 917 | 26 | 762 | 762 | 565 | 470 | 520 | 380 | 150 | 280 | 300 | 200 | 200 | 220 | 150 | 120 | 640 | 20/27 | 585 | 40 | 580 | 16/27 | 525 | 38 | |

| CME | 400/450 | 703 | 824.5 | 781 | 917 | 26 | 800 | 864 | 762 | 521 | 580 | 380 | 150 | 280 | 400 | 200 | 200 | 220 | 150 | 120 | 640 | 20/27 | 585 | 40 | 580 | 16/27 | 525 | 30 | |

| BLE | 450/500 | 703 | 824.6 | 781 | 917 | 26 | 800 | 838 | 584 | 495 | 570 | 450 | 150 | 350 | 300 | 200 | 200 | 220 | 150 | 120 | 715 | 20/30 | 650 | 42 | 640 | 20/27 | 585 | 40 | |

| CME | 450/500 | 703 | 824.5 | 781 | 917 | 32 | 800 | 864 | 610 | 518 | 560 | 450 | 150 | 350 | 300 | 200 | 200 | 220 | 150 | 120 | 715 | 20/30 | 650 | 42 | 640 | 20/27 | 585 | 40 | |

| 6 | DME | 450/500 | 812 | 952.5 | 915 | 1042 | 32 | 889 | 915 | 762 | 572 | 630 | 432 | 165 | 330 | 407 | 203 | 305 | 305 | 165 | 203 | 715 | 20/30 | 650 | 42 | 640 | 20/27 | 585 | 40 |

| CME | 500/600 | 812 | 952.2 | 915 | 1042 | 33 | 940 | 1067 | 745 | 560 | 596 | 550 | 205 | 400 | 400 | 230 | 285 | 373 | 205 | 225 | 840 | 20/33 | 770 | 48 | 715 | 20/30 | 650 | 42 | |

| ALE | 600/600 | 892 | 1010.5 | 995 | 1122 | 33 | 940 | 915 | 610 | 559 | 660 | 576 | 200 | 440 | 300 | 200 | 200 | 416 | 200 | 280 | 840 | 20/33 | 770 | 48 | 840 | 20/33 | 770 | 48 | |

| CME | 600/600 | 892 | 1010.5 | 995 | 1122 | 33 | 940 | 915 | 610 | 559 | 660 | 576 | 200 | 440 | 300 | 200 | 200 | 416 | 200 | 280 | 840 | 20/33 | 770 | 48 | 840 | 20/33 | 770 | 48 | |

| ALE | 800/800 | 892 | 1010.5 | 995 | 1122 | 33 | 1160 | 1143 | 762 | 651 | 685 | 550 | 225 | 400 | 400 | 230 | 285 | 373 | 205 | 225 | 1025 | 24/36 | 950 | 58 | 1025 | 24/36 | 950 | 58 |